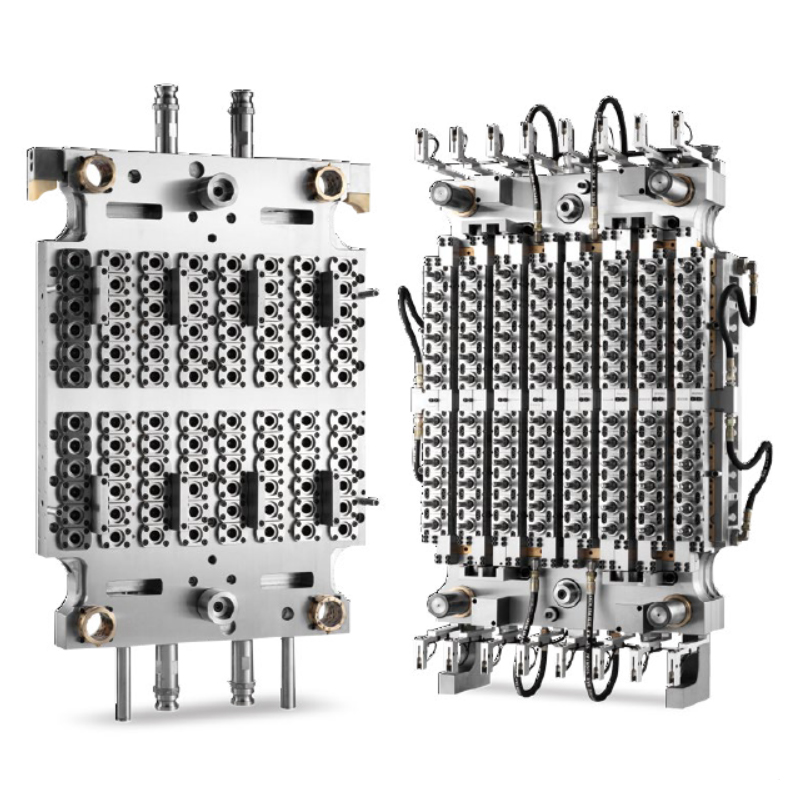

PET Preform Injection Mould Renovation & Refurbishment

Transforming bottle preform molds and parts to achieve bottle preform optimization needs

More flexible production methods to adapt to the market?

Cold half mold transformation of PET bottle preform mold

Change brand usage at Jingyida, HUSK, MHT, OTTO, SIPA

Replace the following molded parts on the mold: core, lip, cavity, & base

Replace the formed parts on the existing mold frame to achieve the PT bottle preform structure and various

Variety changes to meet customer needs

Implementation of bottle preform lightweight project

Quickly change the screw mouth of the bottle preform

PET mold parts of factory quality

Perfect fit with various mold components from the original factory

Less investment compared to original parts

PET Mold 「Renovation」 Project

Even longer than before

Cold half mold refurbishment

Explanation: Due to long-term operation of the mold, the conical surfaces used for locking the mold between rows of parts wear out, resulting in the disappearance of preload and causing flash defects on the bottle embryo mold line.

The sealing failure caused by long-term friction between the valve needle and the mold base, as well as the wear and deformation caused by long-term friction and compression of all structural sliding components.

Cold half mold refurbishment is suitable for the following molds

Brand: DEMARK HUSKY MHT OTTO

Hot half mold refurbishment

Prolonged high-temperature continuous operation may lead to the failure of basic positioning components and deviation in the positioning of the splitter plate. Vulnerable parts undergo relative wear and tear during long-term operation, which seriously endangers the operation of the needle valve system, the thermal balance of the hot runner, and the sealing performance.

Hot half mold refurbishment is suitable for the following molds

Brand: DEMARK HUSKY MHT